State-of-the-Art & Key Highlights of Our Infrastructure

At our organization, we take immense pride in our state-of-the-art apparel manufacturing infrastructure, which stands as a testament to our commitment to excellence and innovation. Spanning over 70,000 square feet, our expansive facility is meticulously designed to facilitate seamless operations and optimize productivity at every stage of the manufacturing process.

- Strategic Division of Space: Our manufacturing facility is strategically divided to ensure efficient operations and optimal space utilization. With 30,000 square feet dedicated to Cutting, Sampling, and Inventory management, and an additional 40,000 square feet allocated for Admin Office, Sewing & Lab, and utility areas, we have created a dynamic environment that fosters innovation and productivity.

- Dedicated Workstations and Segmented Areas: Our factory layout is carefully organized into dedicated workstations and segmented areas, each designed to accommodate specific stages of the production process. This segmentation allows for efficient workflow management and ensures smooth transitions between production stages.

- Safety and Environmental Compliance: Safety and environmental sustainability are paramount in our operations. Our factory adheres to strict safety protocols and environmental standards to provide a safe and healthy working environment for our employees and minimize our ecological footprint.

- Workflow Controlled by Stage ERP System: Our entire production process is streamlined and managed through the Stage ERP system, ensuring seamless coordination and real-time monitoring of all operations.

- State-of-the-Art Equipment and Machinery: We have invested significantly in acquiring the latest and most advanced equipment and machinery available in the industry. From cutting-edge CAD systems and automated cutting machines to innovative sewing machines and value-added machinery, our infrastructure is equipped with cutting-edge technology to support precision manufacturing and superior product quality.

- Commitment to Quality and Excellence: Quality is at the heart of everything we do. Our manufacturing infrastructure is designed to uphold the highest standards of quality and excellence in every aspect of our operations. From raw material procurement to finished product delivery, we adhere to stringent quality control measures and rigorous inspection protocols to ensure that every garment that leaves our facility meets or exceeds customer expectations.

- Focus on Innovation and Productivity: Our manufacturing infrastructure is a testament to our steadfast dedication to innovation and productivity. We are committed to staying at the forefront of technological advancements, constantly seeking new ways to optimize our processes and improve operational efficiency. By harnessing the power of innovation, we aim to elevate the standards of our industry and exceed the expectations of our clients.

In conclusion, our manufacturing infrastructure embodies our dedication to innovation and productivity. By embracing new technologies and digitization, we empower our team to achieve operational excellence and deliver unparalleled value to our clients. Through a relentless pursuit of improvement, we continue to set new benchmarks for success in the apparel industry.

Storage Infrastructure:

In our manufacturing facility, Storage management plays a crucial role in ensuring the smooth flow of operations. Here’s an overview of our storage

infrastructure:

Fabric & Accessories Storage:

- Fabric storage is a pivotal aspect of our inventory management system. Fabrics are stored in pallet form to optimize space utilization and facilitate

easy access. - Each rack is allocated for specific types or categories of fabric, and a barcode system is employed for efficient tracking and retrieval.

- Our inventory management system, driven by ERP (Enterprise Resource Planning) software, ensures accurate allocation of fabrics and trims based on production requirements.

- Racking is strategically designed for overall intralogistics optimization, enabling faster and more efficient operations.

Material Handling:

- Material handling is streamlined to ensure the seamless movement of goods within the facility.

- Stackers & Trolley are utilized for the easy and efficient transportation of materials, allowing for swift and precise handling.

- The use of stackers minimizes manual labor and reduces the risk of damage to materials during transportation, enhancing overall operational efficiency.

At our facility, we prioritize the optimization of storage and inventory

management processes to ensure timely production and delivery of high-quality garments. By leveraging advanced technologies and efficient

material handling practices, we maintain a well-organized and dynamic

inventory system that meets the demands of our production schedule and

customer requirements.

State-of-the-Art & Key Highlights of Our Infrastructure

At our organization, we take immense pride in our state-of-the-art apparel manufacturing infrastructure, which stands as a testament to our commitment to excellence and innovation. Spanning over 70,000 square feet, our expansive facility is meticulously designed to facilitate seamless operations and optimize productivity at every stage of the manufacturing process.

- Strategic Division of Space: Our manufacturing facility is strategically divided to ensure efficient operations and optimal space utilization. With 30,000 square feet dedicated to Cutting, Sampling, and Inventory management, and an additional 40,000 square feet allocated for Admin Office, Sewing & Lab, and utility areas, we have created a dynamic environment that fosters innovation and productivity.

- Dedicated Workstations and Segmented Areas: Our factory layout is carefully organized into dedicated workstations and segmented areas, each designed to accommodate specific stages of the production process. This segmentation allows for efficient workflow management and ensures smooth transitions between production stages.

- Safety and Environmental Compliance: Safety and environmental sustainability are paramount in our operations. Our factory adheres to strict safety protocols and environmental standards to provide a safe and healthy working environment for our employees and minimize our ecological footprint.

- Workflow Controlled by Stage ERP System: Our entire production process is streamlined and managed through the Stage ERP system, ensuring seamless coordination and real-time monitoring of all operations.

- State-of-the-Art Equipment and Machinery: We have invested significantly in acquiring the latest and most advanced equipment and machinery available in the industry. From cutting-edge CAD systems and automated cutting machines to innovative sewing machines and value-added machinery, our infrastructure is equipped with cutting-edge technology to support precision manufacturing and superior product quality.

- Commitment to Quality and Excellence: Quality is at the heart of everything we do. Our manufacturing infrastructure is designed to uphold the highest standards of quality and excellence in every aspect of our operations. From raw material procurement to finished product delivery, we adhere to stringent quality control measures and rigorous inspection protocols to ensure that every garment that leaves our facility meets or exceeds customer expectations.

- Focus on Innovation and Productivity: Our manufacturing infrastructure is a testament to our steadfast dedication to innovation and productivity. We are committed to staying at the forefront of technological advancements, constantly seeking new ways to optimize our processes and improve operational efficiency. By harnessing the power of innovation, we aim to elevate the standards of our industry and exceed the expectations of our clients.

In conclusion, our manufacturing infrastructure embodies our dedication to innovation and productivity. By embracing new technologies and digitization, we empower our team to achieve operational excellence and deliver unparalleled value to our clients. Through a relentless pursuit of improvement, we continue to set new benchmarks for success in the apparel industry.

Storage Infrastructure:

In our manufacturing facility, Storage management plays a crucial role in ensuring the smooth flow of operations. Here’s an overview of our storage

infrastructure:

Fabric & Accessories Storage:

- Fabric storage is a pivotal aspect of our inventory management system. Fabrics are stored in pallet form to optimize space utilization and facilitate

easy access. - Each rack is allocated for specific types or categories of fabric, and a barcode system is employed for efficient tracking and retrieval.

- Our inventory management system, driven by ERP (Enterprise Resource Planning) software, ensures accurate allocation of fabrics and trims based on production requirements.

- Racking is strategically designed for overall intralogistics optimization, enabling faster and more efficient operations.

Material Handling:

- Material handling is streamlined to ensure the seamless movement of goods within the facility.

- Stackers & Trolley are utilized for the easy and efficient transportation of materials, allowing for swift and precise handling.

- The use of stackers minimizes manual labor and reduces the risk of damage to materials during transportation, enhancing overall operational efficiency.

At our facility, we prioritize the optimization of storage and inventory

management processes to ensure timely production and delivery of high-quality garments. By leveraging advanced technologies and efficient

material handling practices, we maintain a well-organized and dynamic

inventory system that meets the demands of our production schedule and

customer requirements.

In-House Lab Facility:

Our organization prides itself on housing a cutting-edge, highly equipped in-house laboratory dedicated to conducting a comprehensive range of physical and basic chemical tests with unparalleled precision. We adhere to AATCC and ISO standards to ensure the reliability and accuracy of our testing procedures.

Our commitment to quality assurance extends to every aspect of our operations, and our in-house lab facility plays a crucial role in ensuring that our products meet the highest standards of quality, durability, and performance. With state-of-the-art equipment, experienced technicians, and specialized testing capabilities, we provide our customers with the confidence that our products undergo rigorous testing to ensure their excellence.

Design & Sample:-

In our Design & Sample, we blend creativity with precision to bring innovative ideas to life and ensure the highest quality standards in our apparel manufacturing process. Here’s an overview of our department’s capabilities:

- Creative Design Expertise:

- Our team comprises skilled designers with a passion for creativity and a keen eye for trends. They stay updated with the latest fashion trends, market demands, and customer preferences to develop fresh and captivating designs that resonate with our target audience.

- Advanced Design Software:

We employ cutting-edge technology and advanced software to ensure precision and efficiency throughout the pattern making and sampling process. Here’s an overview of our capabilities:

- Cutting Edge Pattern Making CAD Software:

- We utilize industry-leading CAD software such as TUKA TECH from the US and INVENTEX from Italy. These software solutions offer sophisticated tools for pattern making, grading, and marker planning.

- Automatic Pattern Cutting Machine:

- Our facility is equipped with automatic pattern cutting machines that enable high-speed and accurate cutting of patterns. These machines ensure consistency and precision in every cut, resulting in uniform and well-fitted garments.

- Auto Cut Planner:

- With the help of our CAD software, we utilize an Auto Cut Planner feature to optimize fabric consumption. By analyzing patterns and marker placements digitally, we can minimize fabric wastage and maximize material utilization, leading to cost savings and sustainable manufacturing practices.

- Exact Fabric Consumption Calculation:

- Through CAD technology, we can calculate the exact fabric consumption for each garment design. This precise calculation allows us to accurately estimate fabric requirements for production runs, ensuring optimal inventory management and cost control.

- Breathable Fit Analysis:

- Using CAD software, we conduct a comprehensive analysis of garment fit to ensure breathability and comfort. By simulating garment designs digitally, we can assess the fit and functionality of the apparel, making necessary adjustments to enhance wearer comfort and satisfaction.

In conclusion, our Design & Sample Department serves as the creative engine driving innovation and excellence in our apparel manufacturing process. By combining creative expertise with advanced technology and meticulous attention to detail, we strive to deliver high-quality, on-trend garments that exceed customer expectations and set new standards of excellence in the industry.

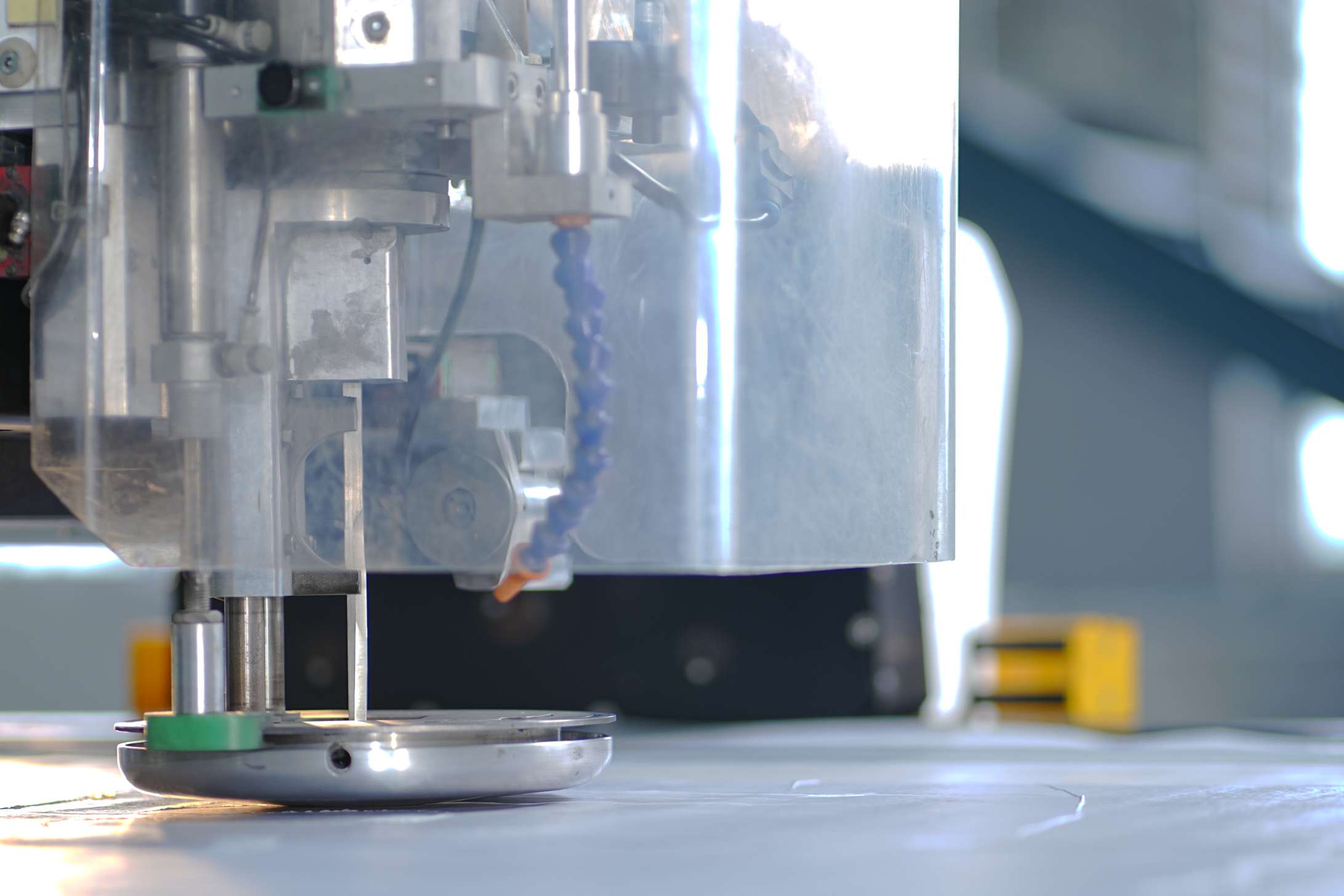

Apparel Manufacturing Flow: Smart Integrated Cutting Process

In our cutting room, we integrate cutting-edge technology from Cosma Technology, a leading provider of automated cutting solutions for the garment industry. Our cutting process is meticulously designed to optimize efficiency, accuracy, and productivity. Here’s an overview of our cutting process:

- Cosma Technology Integration:

- Our cutting room is fully integrated with Cosma Technology’s advanced solutions, including:

- Digital Cutting Room: Utilizing state-of-the-art digital cutting technology to enhance precision and speed in the cutting process.

- Cut Planning Software: Implementing intelligent software solutions for efficient and optimized cut planning.

- Cutting Room Hardware:

- We have invested in cutting-edge hardware equipment from Cosma Technology, including:

- Auto Loader: Automated loading system for efficient material handling and preparation.

- Automated Spreading Machine: Utilizing Cosma Venus 3 and Ram Dukes machines for automated spreading of fabric, ensuring consistency and accuracy.

- Conveyor Table: Streamlining material flow and movement within the cutting room for seamless operations.

- Cosmo Postmarter 20 Labeling Machine: Automating the labeling process for efficient tracking and identification of cut pieces.

- Smart Cutting Machine (Cosmo Smart 3): Implementing advanced cutting machines for precise and efficient cutting of fabric.

In conclusion, our cutting process exemplifies our commitment to leveraging cutting-edge technology to optimize efficiency, accuracy, and productivity in apparel manufacturing. Through our partnership with Cosma Technology and the integration of advanced software and hardware solutions, we deliver exceptional results to meet the evolving needs of our customers.

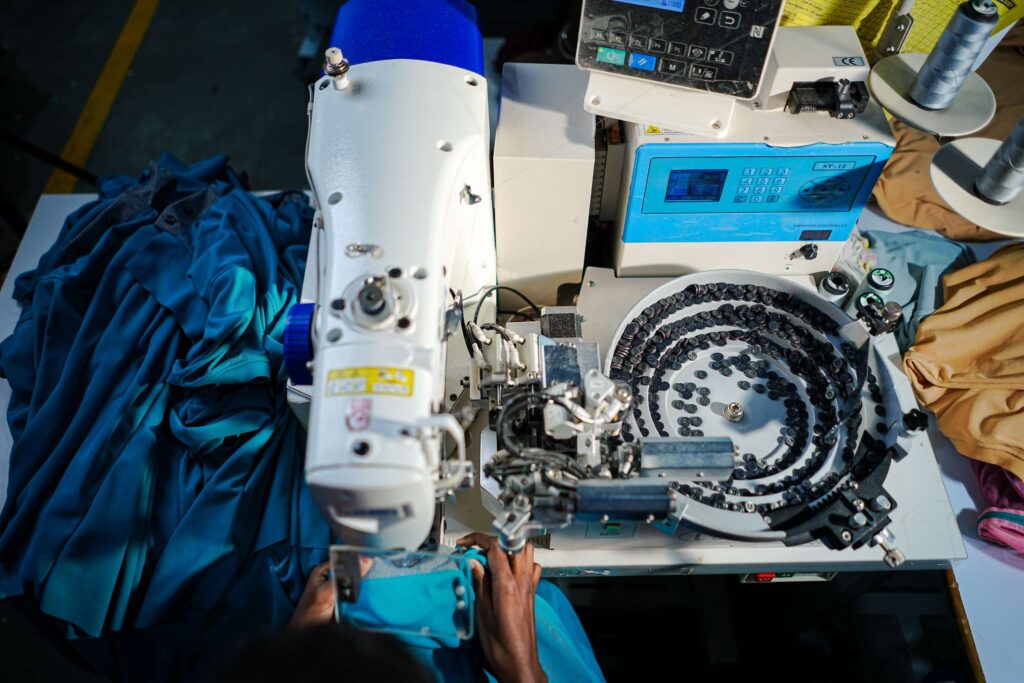

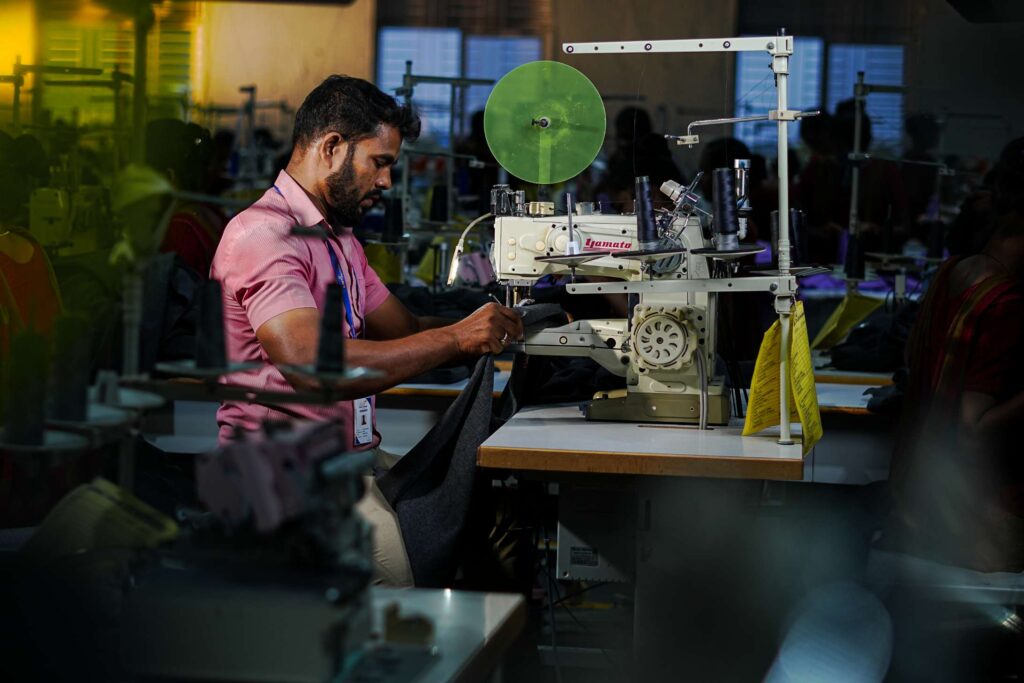

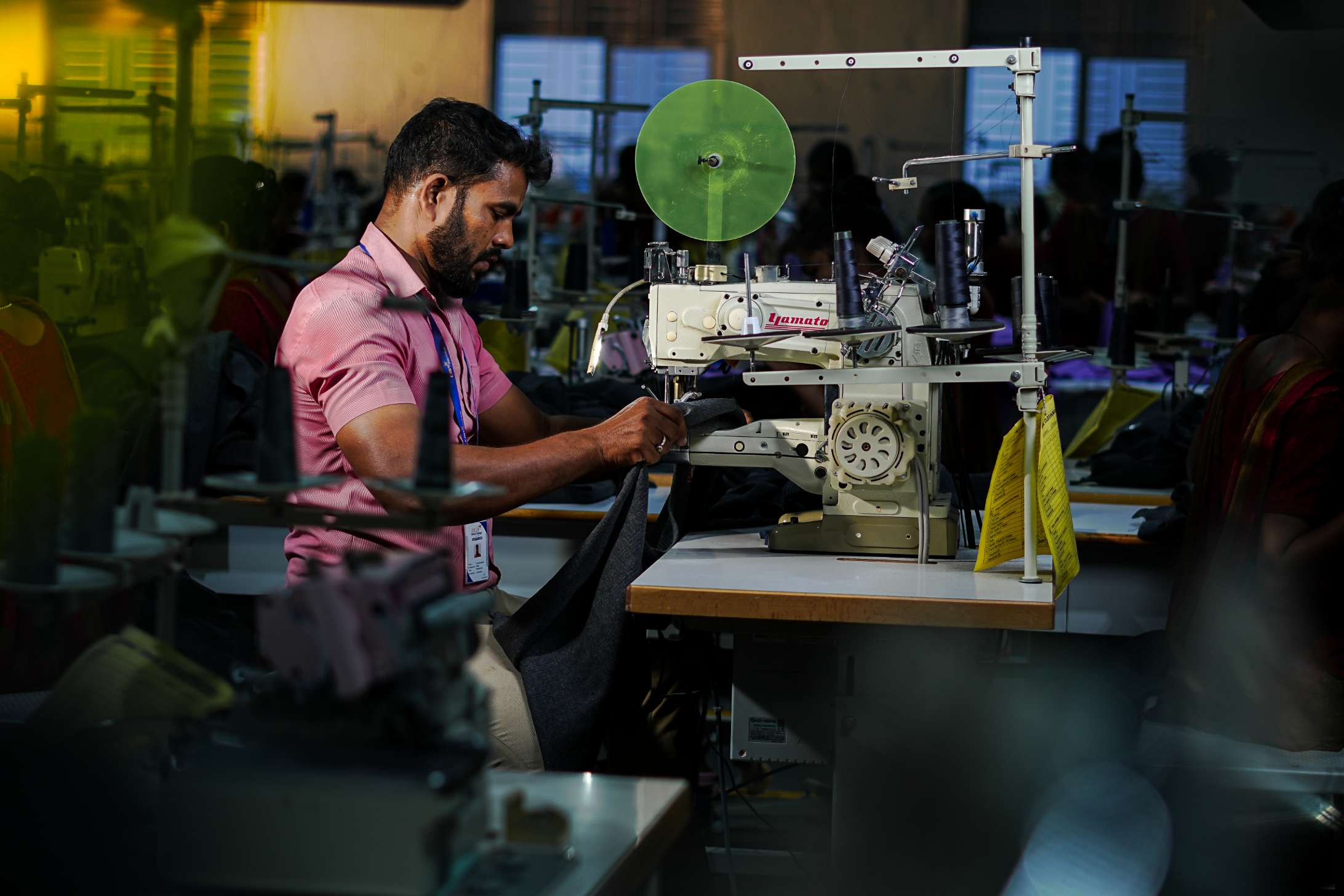

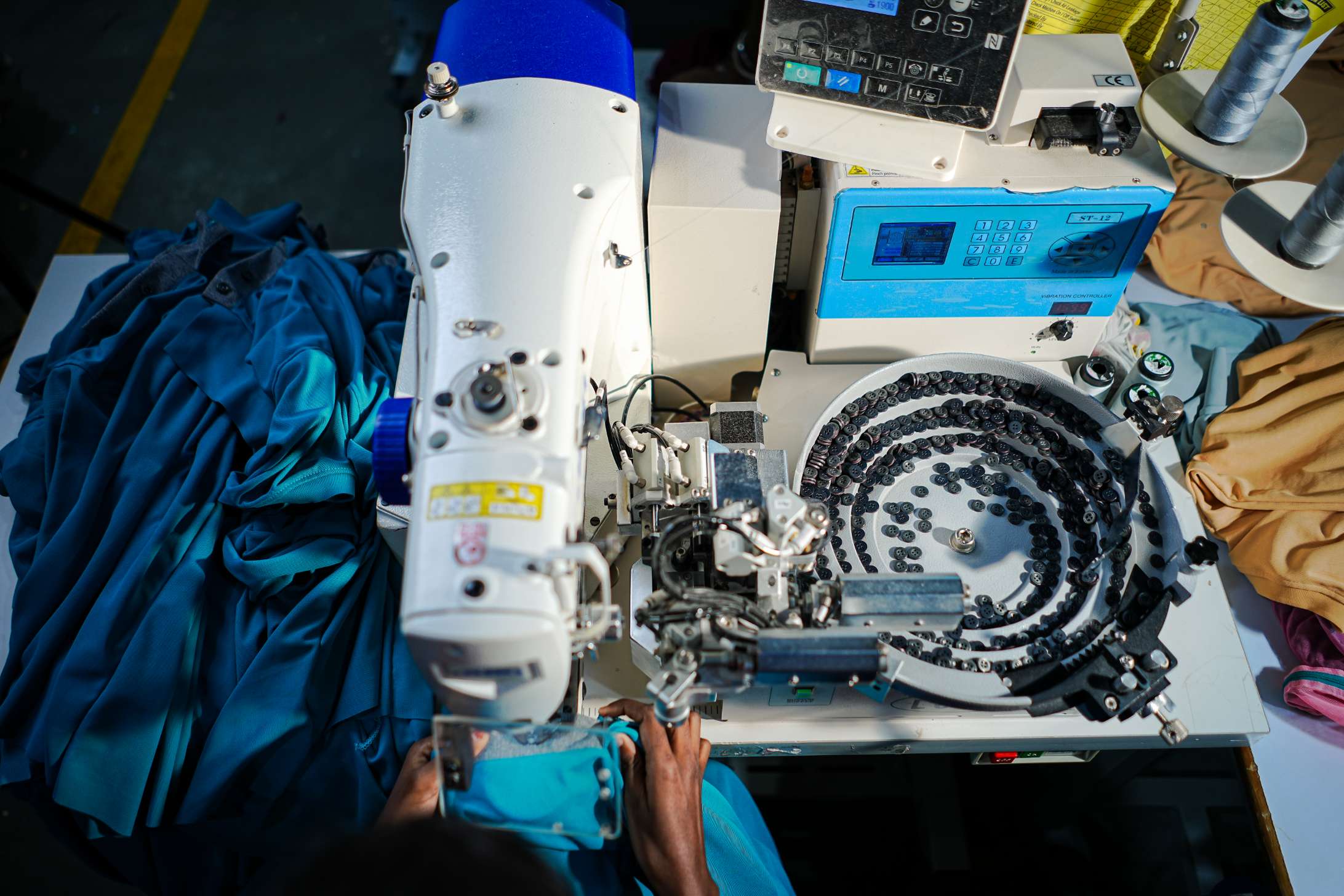

Sewing

Production Capacity and Technology:

- Our sophisticated manufacturing unit boasts an impressive installed production capacity of 270,000 garments and 120,000 innerwear garments

per month. - Equipped with cutting-edge Japanese technology from Pegasus and Juki of 400 machines, our sewing unit is optimized for integrated garmenting, guaranteeing seamless production processes and the delivery of high-quality output.

- We harness the power of automated sewing machines to enhance efficiency, precision, and consistency in our operations. This approach not only minimizes errors but also maximizes productivity, resulting in labor-saving and quality-configured products.

- Our sewing capabilities encompass the entire range of apparel, accommodating various types of prints and embroidery to meet the diverse

needs of our clientele.

Finishing:

The Finishing Department plays a pivotal role in ensuring the impeccable presentation and quality of our garments. Staffed by a team of highly trained professionals and equipped with state-of-the-art technology, this department ensures that each garment meets the highest standards of excellence before it reaches our customers.

Key Features:

- Steam Ironing:

- Our Finishing Department is equipped with Ramson steam ironing technology, renowned for its ability to deliver flawless, crease-free finishes. This advanced equipment ensures that garments are pressed to perfection, enhancing their overall appearance and wear ability.

- Needle Detection:

- Upholding our commitment to product safety and quality, all finished goods undergo a rigorous 100% needle detection process. This ensures that garments are free from any needle or metal parts during the production process, providing peace of mind to both our customers and end-users.

- Airport Area Access:

- Upon completion of the finishing process, garments are meticulously packaged and prepared for transportation to the airport area. Additionally, each garment is scanned for barcode identification to ensure adherence to quality standards and facilitate efficient logistics management.

- Automated Packing List Generation:

- Goods undergo automated packing and scanning processes, with packing lists generated seamlessly through our ERP system. This ensures accuracy and efficiency in inventory management and shipment preparation. Moreover, our system is capable of integrating with customer software, facilitating seamless communication and collaboration.

The Finishing Department serves as the final checkpoint in our manufacturing process, guaranteeing that each garment meets our stringent quality standards and exceeds customer expectations. With a focus on cutting-edge technology, skilled craftsmanship, and unwavering dedication to quality assurance, we strive to deliver garments that delight our customers with their impeccable finish and presentation.

In-House Lab Facility:

Our organization prides itself on housing a cutting-edge, highly equipped in-house laboratory dedicated to conducting a comprehensive range of physical and basic chemical tests with unparalleled precision. We adhere to AATCC and ISO standards to ensure the reliability and accuracy of our testing procedures.

Our commitment to quality assurance extends to every aspect of our operations, and our in-house lab facility plays a crucial role in ensuring that our products meet the highest standards of quality, durability, and performance. With state-of-the-art equipment, experienced technicians, and specialized testing capabilities, we provide our customers with the confidence that our products undergo rigorous testing to ensure their excellence.

Design & Sample:-

In our Design & Sample, we blend creativity with precision to bring innovative ideas to life and ensure the highest quality standards in our apparel manufacturing process. Here’s an overview of our department’s capabilities:

- Creative Design Expertise:

- Our team comprises skilled designers with a passion for creativity and a keen eye for trends. They stay updated with the latest fashion trends, market demands, and customer preferences to develop fresh and captivating designs that resonate with our target audience.

- Advanced Design Software:

We employ cutting-edge technology and advanced software to ensure precision and efficiency throughout the pattern making and sampling process. Here’s an overview of our capabilities:

- Cutting Edge Pattern Making CAD Software:

- We utilize industry-leading CAD software such as TUKA TECH from the US and INVENTEX from Italy. These software solutions offer sophisticated tools for pattern making, grading, and marker planning.

- Automatic Pattern Cutting Machine:

- Our facility is equipped with automatic pattern cutting machines that enable high-speed and accurate cutting of patterns. These machines ensure consistency and precision in every cut, resulting in uniform and well-fitted garments.

- Auto Cut Planner:

- With the help of our CAD software, we utilize an Auto Cut Planner feature to optimize fabric consumption. By analyzing patterns and marker placements digitally, we can minimize fabric wastage and maximize material utilization, leading to cost savings and sustainable manufacturing practices.

- Exact Fabric Consumption Calculation:

- Through CAD technology, we can calculate the exact fabric consumption for each garment design. This precise calculation allows us to accurately estimate fabric requirements for production runs, ensuring optimal inventory management and cost control.

- Breathable Fit Analysis:

- Using CAD software, we conduct a comprehensive analysis of garment fit to ensure breathability and comfort. By simulating garment designs digitally, we can assess the fit and functionality of the apparel, making necessary adjustments to enhance wearer comfort and satisfaction.

In conclusion, our Design & Sample Department serves as the creative engine driving innovation and excellence in our apparel manufacturing process. By combining creative expertise with advanced technology and meticulous attention to detail, we strive to deliver high-quality, on-trend garments that exceed customer expectations and set new standards of excellence in the industry.

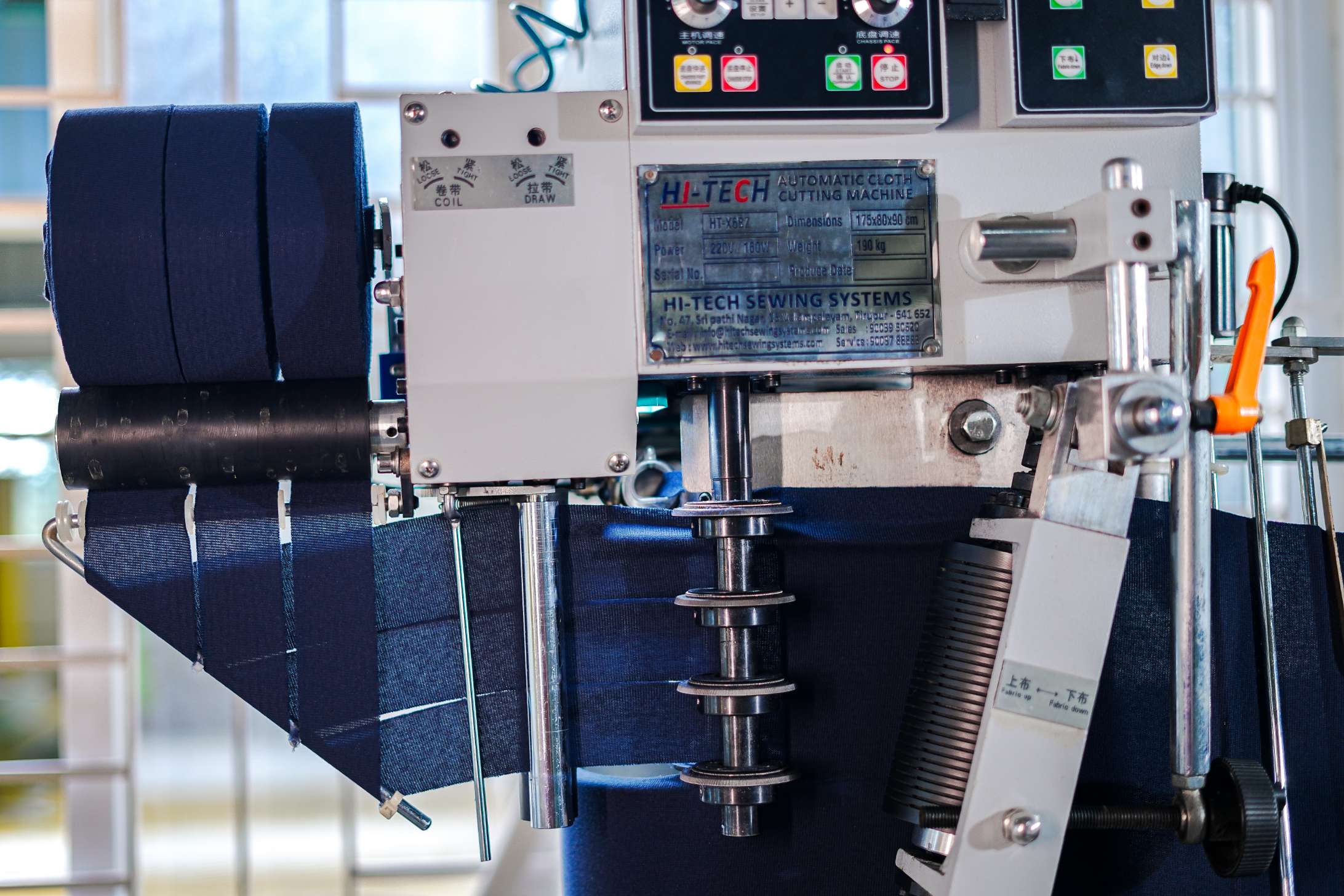

Apparel Manufacturing Flow: Smart Integrated Cutting Process

In our cutting room, we integrate cutting-edge technology from Cosma Technology, a leading provider of automated cutting solutions for the garment industry. Our cutting process is meticulously designed to optimize efficiency, accuracy, and productivity. Here’s an overview of our cutting process:

- Cosma Technology Integration:

- Our cutting room is fully integrated with Cosma Technology’s advanced solutions, including:

- Digital Cutting Room: Utilizing state-of-the-art digital cutting technology to enhance precision and speed in the cutting process.

- Cut Planning Software: Implementing intelligent software solutions for efficient and optimized cut planning.

- Cutting Room Hardware:

- We have invested in cutting-edge hardware equipment from Cosma Technology, including:

- Auto Loader: Automated loading system for efficient material handling and preparation.

- Automated Spreading Machine: Utilizing Cosma Venus 3 and Ram Dukes machines for automated spreading of fabric, ensuring consistency and accuracy.

- Conveyor Table: Streamlining material flow and movement within the cutting room for seamless operations.

- Cosmo Postmarter 20 Labeling Machine: Automating the labeling process for efficient tracking and identification of cut pieces.

- Smart Cutting Machine (Cosmo Smart 3): Implementing advanced cutting machines for precise and efficient cutting of fabric.

In conclusion, our cutting process exemplifies our commitment to leveraging cutting-edge technology to optimize efficiency, accuracy, and productivity in apparel manufacturing. Through our partnership with Cosma Technology and the integration of advanced software and hardware solutions, we deliver exceptional results to meet the evolving needs of our customers.

Sewing

Production Capacity and Technology:

- Our sophisticated manufacturing unit boasts an impressive installed production capacity of 270,000 garments and 120,000 innerwear garments

per month. - Equipped with cutting-edge Japanese technology from Pegasus and Juki of 400 machines, our sewing unit is optimized for integrated garmenting, guaranteeing seamless production processes and the delivery of high-quality output.

- We harness the power of automated sewing machines to enhance efficiency, precision, and consistency in our operations. This approach not only minimizes errors but also maximizes productivity, resulting in labor-saving and quality-configured products.

- Our sewing capabilities encompass the entire range of apparel, accommodating various types of prints and embroidery to meet the diverse

needs of our clientele.

Finishing:

The Finishing Department plays a pivotal role in ensuring the impeccable presentation and quality of our garments. Staffed by a team of highly trained professionals and equipped with state-of-the-art technology, this department ensures that each garment meets the highest standards of excellence before it reaches our customers.

Key Features:

- Steam Ironing:

- Our Finishing Department is equipped with Ramson steam ironing technology, renowned for its ability to deliver flawless, crease-free finishes. This advanced equipment ensures that garments are pressed to perfection, enhancing their overall appearance and wear ability.

- Needle Detection:

- Upholding our commitment to product safety and quality, all finished goods undergo a rigorous 100% needle detection process. This ensures that garments are free from any needle or metal parts during the production process, providing peace of mind to both our customers and end-users.

- Airport Area Access:

- Upon completion of the finishing process, garments are meticulously packaged and prepared for transportation to the airport area. Additionally, each garment is scanned for barcode identification to ensure adherence to quality standards and facilitate efficient logistics management.

- Automated Packing List Generation:

- Goods undergo automated packing and scanning processes, with packing lists generated seamlessly through our ERP system. This ensures accuracy and efficiency in inventory management and shipment preparation. Moreover, our system is capable of integrating with customer software, facilitating seamless communication and collaboration.

The Finishing Department serves as the final checkpoint in our manufacturing process, guaranteeing that each garment meets our stringent quality standards and exceeds customer expectations. With a focus on cutting-edge technology, skilled craftsmanship, and unwavering dedication to quality assurance, we strive to deliver garments that delight our customers with their impeccable finish and presentation.